In the field of sand and aggregate processing, the presence of mud, silt, and fine impurities can significantly affect the quality of end products, impacting construction strength, concrete performance, and overall process efficiency. The RXD series sand washing machine stands out as a specialized cleaning solution designed to tackle these challenges comprehensively. By integrating advanced mechanical action with optimized water flow dynamics, it delivers consistent removal of unwanted particles, resulting in cleaner sand and a more balanced gradation curve. Understanding its working principles helps clarify why it is regarded as a reliable “cleaning expert” in the industry.

The Core Challenge: Mud and Impurities in Raw Sand

Natural and crushed sand often contains surface-adhered clay, silt, and dust particles. These contaminants cling tightly to sand grains due to moisture and electrostatic forces, making simple rinsing ineffective. If not removed, they increase water demand in concrete mixes, reduce bonding strength, and cause uneven gradation, which leads to segregation during transport and application. Moreover, excessive fines can clog equipment downstream, lowering production efficiency. Therefore, effective separation of these impurities without damaging the desirable sand particles is critical.

Mechanical Action Meets Hydraulic Precision

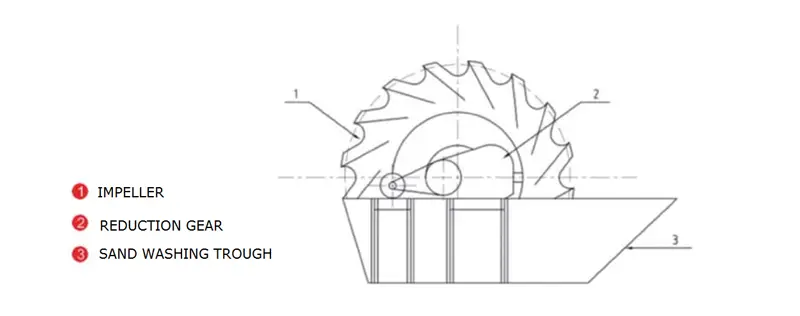

The RXD series sand washing machine employs a combination of rotating agitation and controlled hydraulic flow. Its robust impeller system lifts and tumbles the sand-water mixture, creating strong shear forces that detach stubborn mud layers from grain surfaces. Simultaneously, strategically directed water jets scour the material, ensuring thorough penetration into interstitial spaces where fine impurities tend to lodge. This dual-action mechanism surpasses traditional washing methods that rely solely on soaking or weak agitation, achieving higher impurity removal rates in shorter cycles.

Controlled Classification Enhances Gradation Uniformity

Beyond cleaning, the RXD series incorporates classification zones within its tub or screening systems. As the cleaned sand settles, particles are separated by size through velocity differences in upward-flowing water. Larger grains settle faster and are discharged first, while finer particles remain suspended longer and are either recirculated for further washing or removed as tailings. This dynamic sorting refines the particle distribution curve, producing sand with tighter gradation tolerances. Improved gradation means better packing density in concrete and asphalt, enhancing structural integrity and reducing void ratios.

Reduced Fines Content Supports Sustainable Production

By efficiently extracting silt and clay, the RXD series lowers the percentage of minus-75-micron particles in the final product. This reduction minimizes excess binder requirement in cementitious applications and lessens environmental impact from fines disposal. In addition, cleaner sand reduces wear on downstream machinery such as crushers, screens, and conveyor components, extending service life and cutting operational costs. The result is a more sustainable production cycle with fewer resources wasted on reprocessing or rectifying poor-quality feedstock.

Adaptability Across Feed Conditions

The design of the RXD series accommodates varying feed characteristics, from high-clay content alluvial deposits to crushed stone screenings with embedded dust. Adjustable impeller speeds, water flow rates, and weir gate positions allow operators to tailor the cleaning intensity to specific raw material conditions. Such flexibility ensures stable performance whether processing wet or dry feed, and across different throughput requirements, making the equipment suitable for diverse operational contexts.

Seamless Integration Into Processing Lines

Ease of integration further strengthens its role as a cleaning expert. The RXD series can be positioned after crushing and screening stages with minimal modification to existing plant layouts. Its modular configuration supports both stationary installations and mobile setups, enabling rapid deployment in quarries, river sand operations, or recycling facilities. Coupled with straightforward maintenance routines, it sustains high availability and keeps downtime to a minimum.

In summary, the RXD series sand washing machine excels at removing mud, silt, and fine impurities through a synergy of mechanical agitation and hydraulic precision. Its capacity to enhance sand gradation translates into measurable improvements in product quality, process efficiency, and resource utilization. For operations aiming to elevate cleanliness standards and achieve optimal particle distribution, exploring the capabilities of this equipment offers a pathway to consistently superior outcomes. Discover our range of solutions on our site to see how targeted cleaning technology can refine your sand production workflow.

Post time: Dec-01-2025