Steel Casting of WUJ

Our casting capacity allows us to manufacture, heat-treat and machine ferrous castings from 50g to 24,000kg. Our team of casting and design engineers, metallurgists, CAD operators and machinists makes WUJ Foundry a one-stop shop for all your casting needs.

WUJ Wear-Resistant Alloys include:

- Manganese Steel

12-14% Manganese: Carbon 1.25-1.30, Manganese 12-14%, with other elements;

16-18% Manganese: Carbon 1.25-1.30, Manganese 16-18%, with other elements;

19-21% Manganese: Carbon 1.12-1.38, Manganese 19-21%, with other elements;

22-24% Manganese: Carbon 1.12-1.38, Manganese 22-24%, with other elements;

And various extensions on this basis, such as adding Mo and other elements according to the actual working environment.

- Carbon Steels

Such as: BS3100A1, BS3100A2, SCSiMn1H, ASTMA732-414D, ZG30NiCrMo and so on.

- High Chrome White Iron

- Low Alloy Steels

- Other alloys customized according to user needs

Choosing the right alloys is really very important. As you know Manganese alloys are extremely resilient, and products like cone liners can take a lot strain before they become worn out.

WUJ large range of alloys and our ability to cast to specification means your wear parts will not only last longer, they will do a better job too.

The pathway to determining how much manganese to add to the steel is pure science. We put our metals through rigorous testing before we release a product to the market.

All raw materials will be strictly inspected and relevant records will be kept before being used in the factory. Only qualified raw materials can be put into production.

For each smelting furnace, there are pre - and in-process sampling and test block retention sampling. The data during pouring will be displayed on the large screen of the site. The test block and data shall be stored for at least three years.

Special personnel are assigned to check the mold cavity, and after pouring, the product model and required heat preservation time shall be noted on each sand box in strict accordance with the casting process.

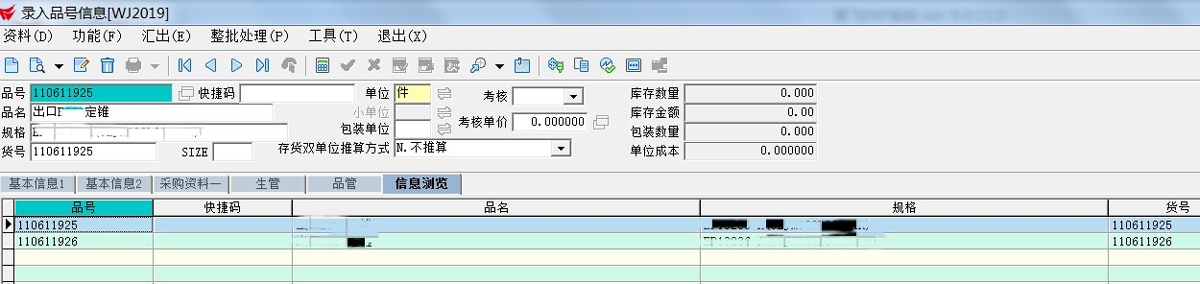

Use ERP system to track and control the whole production process.