Steel Casting of WUJ

Umthamo wethu wokuphosa usivumela ukuba senze, ukunyanga ubushushu kunye nomatshini wokuphosa i-ferrous castings ukusuka kwi-50g ukuya kwi-24,000kg.Iqela lethu leenjineli zokusakha kunye noyilo, ii-metallurgists, ii-CAD kunye neengcali ze-machinists lenza i-WUJ Foundry ibe yindawo enye yokumisa kuzo zonke iimfuno zakho zokuphosa.

I-WUJ Wear-Resistant Alloys ibandakanya:

- Intsimbi yeManganese

I-12-14% I-Manganese: I-Carbon 1.25-1.30, i-Manganese 12-14%, kunye nezinye izinto;

I-16-18% I-Manganese: I-Carbon 1.25-1.30, i-Manganese 16-18%, kunye nezinye izinto;

I-19-21% I-Manganese: I-Carbon 1.12-1.38, i-Manganese 19-21%, kunye nezinye izinto;

22-24% Manganese: Carbon 1.12-1.38, Manganese 22-24%, kunye nezinye izinto;

Kwaye izandiso ezahlukeneyo kwesi siseko, ezinjengokongeza i-Mo kunye nezinye izinto ngokwendawo yokusebenza eyiyo.

- Iintsimbi zeCarbon

Njenge: BS3100A1, BS3100A2, SCSiMn1H, ASTMA732-414D, ZG30NiCrMo njalo njalo.

- High Chrome White Iron

- Iintsimbi ze-Alloy ephantsi

- Ezinye ii-alloys zenziwe ngokweemfuno zabasebenzisi

Ukukhetha i-alloys efanelekileyo kubaluleke kakhulu.Njengoko usazi, iialloyi zeManganese zomelele ngokugqithisileyo, kwaye iimveliso ezifana neecone liners zinokuthatha uxinzelelo olukhulu phambi kokuba ziguge.

I-WUJ uluhlu olukhulu lweealloyi kunye nokukwazi kwethu ukuphosa kwiinkcukacha kuthetha ukuba iindawo zakho zokunxiba aziyi kuhlala nje ixesha elide, ziya kwenza umsebenzi ongcono kakhulu.

Indlela yokufumanisa ukuba ingakanani imanganese eyongezwa kwintsimbi yinzululwazi ecocekileyo.Sibeka iintsimbi zethu ngovavanyo olungqongqo phambi kokuba sikhuphele imveliso kwimarike.

Yonke imathiriyeli ekrwada iya kuhlolwa ngokungqongqo kwaye iirekhodi ezifanelekileyo ziya kugcinwa phambi kokuba zisetyenziswe kumzi-mveliso.Kuphela ziimathiriyeli ekrwada ezisemgangathweni ezinokufakwa kwimveliso.

Kwiziko lokunyibilikisa ngalinye, kukho iisampulu zangaphambili kunye nezingaphakathi kwinkqubo kunye nokugcinwa kwesampulu yebhloko yovavanyo.Idatha ngexesha lokugalela iya kuboniswa kwisikrini esikhulu sesayithi.Ibhloko yovavanyo kunye nedatha iya kugcinwa ubuncinci iminyaka emithathu.

Abasebenzi abakhethekileyo babelwe ukujonga i-mold cavity, kwaye emva kokuthulula, imodeli yemveliso kunye nexesha elifunekayo lokugcinwa kobushushu liya kuqatshelwa kwibhokisi yesanti nganye ngokuhambelana ngokungqongqo nenkqubo yokuphosa.

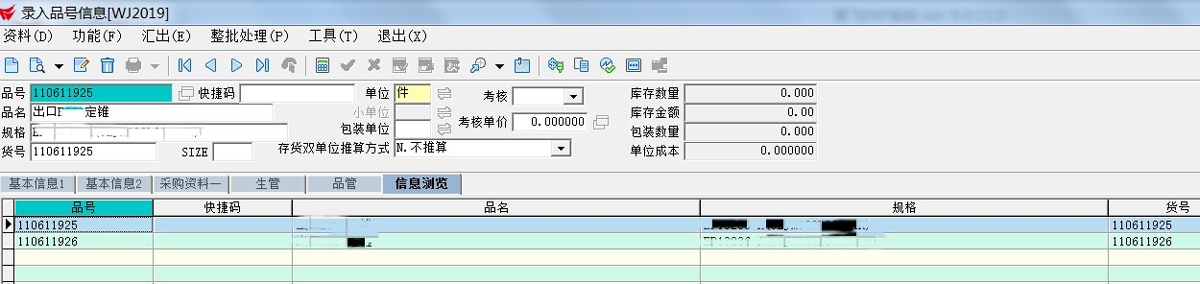

Sebenzisa inkqubo ye-ERP ukulandelela kunye nokulawula yonke inkqubo yemveliso.