Ukusakaza Kwensimbi kwe-WUJ

Umthamo wethu wokuphonsa usivumela ukuthi senze, siphathe ukushisa kanye nomshini wokusakazwa kwensimbi ukusuka ku-50g kuya ku-24,000kg. Ithimba lethu lonjiniyela bokusakaza nokuklama, i-metallurgists, opharetha be-CAD nochwepheshe bemishini lenza i-WUJ Foundry indawo eyodwa yazo zonke izidingo zakho zokusakaza.

I-WUJ Wear-Resistant Alloys ihlanganisa:

- Insimbi yeManganese

I-12-14% I-Manganese: I-Carbon 1.25-1.30, i-Manganese 12-14%, nezinye izakhi;

16-18% I-Manganese: Ikhabhoni 1.25-1.30, iManganese 16-18%, nezinye izakhi;

19-21% I-Manganese: Ikhabhoni 1.12-1.38, iManganese 19-21%, nezinye izakhi;

22-24% Manganese: Carbon 1.12-1.38, Manganese 22-24%, nezinye izakhi;

Nezandiso ezahlukahlukene kulesi sisekelo, njengokwengeza i-Mo nezinye izakhi ngokuya ngendawo yokusebenza yangempela.

- Izinsimbi Zekhabhoni

Njenge: BS3100A1, BS3100A2, SCSiMn1H, ASTMA732-414D, ZG30NiCrMo njalonjalo.

- Insimbi Emhlophe Ye-Chrome Ephakeme

- Izinsimbi ze-Alloy Low

- Amanye ama-alloys enziwe ngokwezifiso ngokuya ngezidingo zomsebenzisi

Ukukhetha ama-alloys afanele kubaluleke kakhulu. Njengoba wazi ukuthi ingxubevange yeManganese iyakwazi ukumelana nokuqina, futhi imikhiqizo efana nama-cone liners ingathatha ubunzima ngaphambi kokuthi iguge.

I-WUJ yohlu olukhulu lwama-alloys kanye nekhono lethu lokusebenzisa imininingwane ethile kusho ukuthi izingxenye zakho ezigugile ngeke zihlale isikhathi eside kuphela, zizokwenza umsebenzi ongcono kakhulu.

Indlela yokunquma ukuthi ingakanani i-manganese okufanele yengezwe ensimbi isayensi emsulwa. Sibeka izinsimbi zethu ngokuhlolwa okunzima ngaphambi kokuba sikhiphe umkhiqizo siye emakethe.

Zonke izinto ezisetshenziswayo zizohlolwa ngokucophelela futhi amarekhodi afanele azogcinwa ngaphambi kokuthi asetshenziswe efekthri. Izinto ezingavuthiwe kuphela ezingafakwa ekukhiqizeni.

Esithandweni somlilo ngasinye sokuncibilikisa, kukhona amasampula angaphambi naphakathi kwenqubo kanye namasampula okugcinwa kwebhulokhi yokuhlola. Idatha ngesikhathi sokuthululwa izoboniswa esikrinini esikhulu sesayithi. Ibhulokhi yokuhlola kanye nedatha izogcinwa okungenani iminyaka emithathu.

Izisebenzi ezikhethekile zabelwe ukuhlola umgodi wokubunjwa, futhi ngemva kokuthululwa, imodeli yomkhiqizo kanye nesikhathi esidingekayo sokulondoloza ukushisa kufanele kuphawulwe ebhokisini lesihlabathi ngalinye ngokuhambisana ngokuqinile nenqubo yokuphonsa.

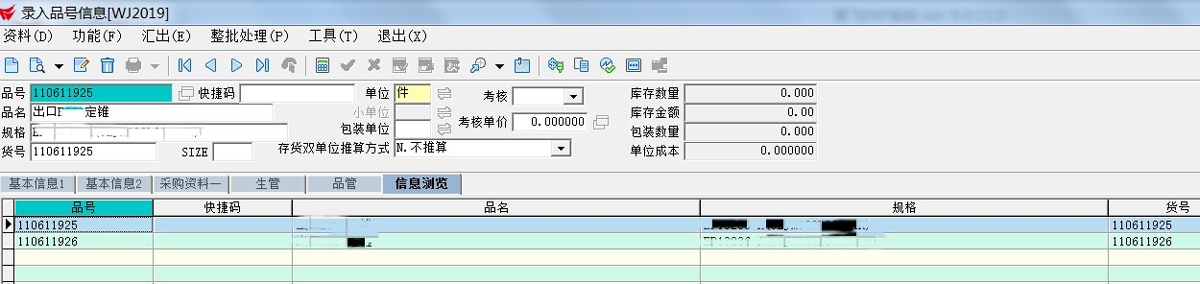

Sebenzisa uhlelo lwe-ERP ukulandelela nokulawula yonke inqubo yokukhiqiza.