Industry News

-

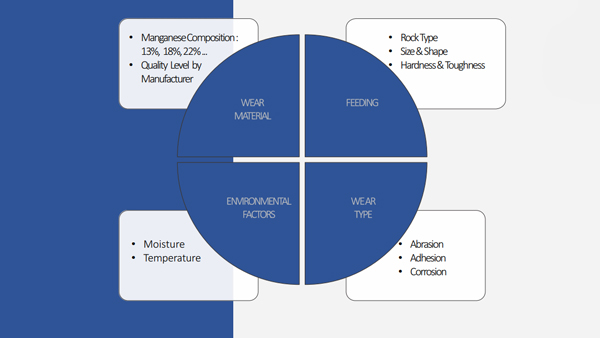

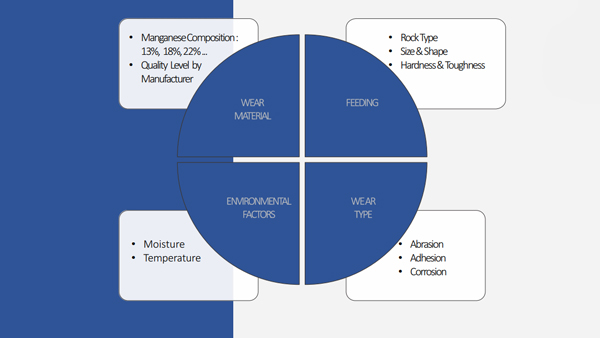

What affects lifetime of wear parts

Wear is produced by 2 elements pressing against each other between a liner and crushing material. During this process small materials from each element become detached . Material fatigue is one important factor, some other factors also affect the crusher’s wear parts’ lifetime, such as listed in ...Read more -

Working principle of vibrating screen

When the vibrating screen is working, the synchronous reverse rotation of the two motors causes the vibrator to generate a reverse excitation force, forcing the screen body to drive the screen mesh to make a longitudinal movement, so that the materials on the screen are periodically thrown forwar...Read more -

What are the classifications of vibrating screens

Mining vibrating screen can be divided into: high-efficiency heavy-duty screen, self-centering vibrating screen, elliptical vibrating screen, dewatering screen, circular vibrating screen, banana screen, linear vibrating screen, etc. Lightweight fine vibrating screen can be divided into: rotary vi...Read more -

How to check and store the vibrating screen

Before leaving the factory, the equipment shall be assembled by precision collection and no-load test run, and can only leave the factory after all indicators are checked to be qualified. Therefore, after the equipment is shipped to the use site, the user shall check whether the parts of the whol...Read more -

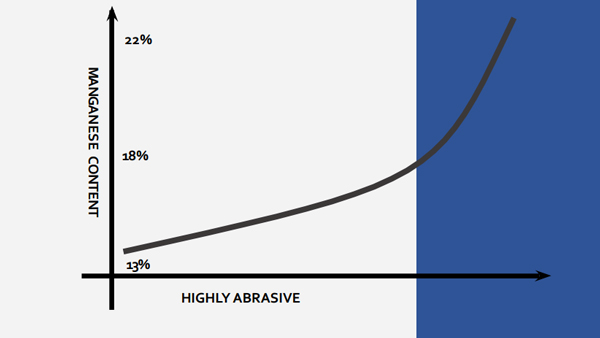

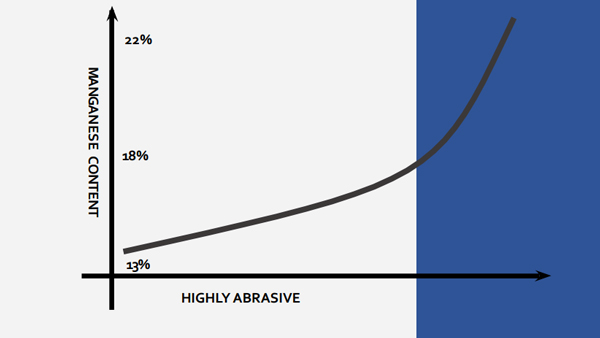

How to choose manganese

Manganese steel is the most common material for crusher wears. All round manganese level and the most common for all applications is 13%, 18% and 22%. What’s the different among them? 13% MANGANESE Available for use in soft low abrasion applications, especially for medium & non-abrasive rock,...Read more