In the sand and gravel processing system, the water volume control of the sand washing machine directly determines the quality of the finished sand and the economic efficiency of production, while the water resource recycling system is the core support for achieving green production. Unreasonable water supply can cause the fine sand loss rate to rise to over 20%, while inefficient water circulation design will increase the consumption of fresh water by 3 to 5 times. This article constructs a scientific and complete water volume control and recycling scheme from three dimensions: parameter optimization, system design, and technical implementation.

First, the core parameters and regulation logic of water volume control for sand washing machines

The essence of water volume control is to achieve a dynamic balance of “cleaning efficiency – resource consumption – finished product quality”, which requires precise setting of key parameters based on the characteristics of raw materials and the type of equipment.

(1) Scientific setting of basic water volume parameters

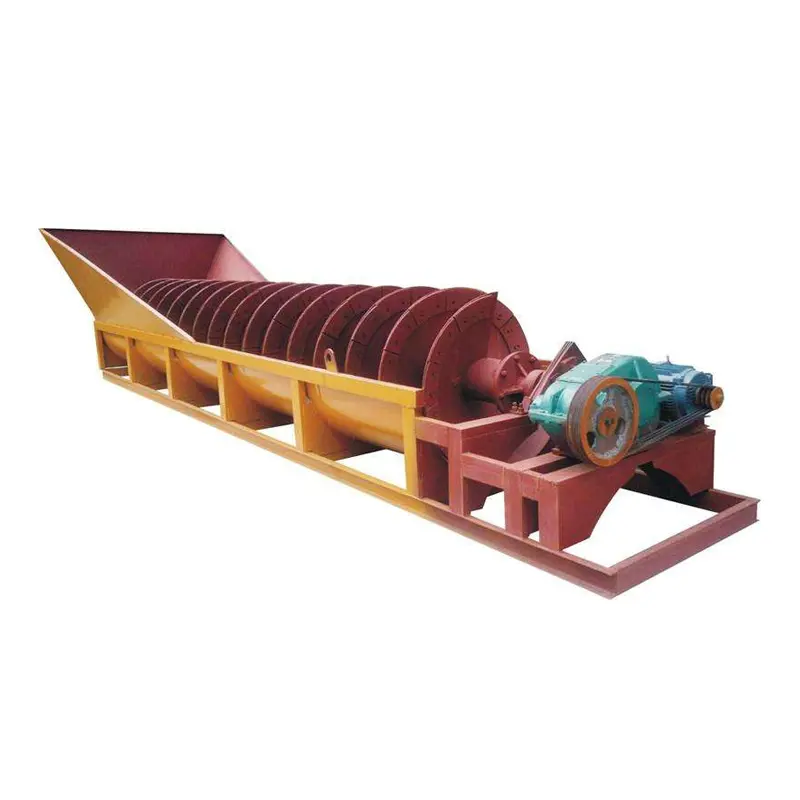

There is a significant difference in water demand between wheel-type sand washing machines and spiral sand washing machines: The single-tank flushing flow rate of wheel-type equipment should be controlled at 5-10L/s. The water flow vortex formed by the rotation of the impeller can peel off impurities on the surface of the sand and gravel. If the flow rate is too high, fine sand with a particle size of ≤0.075mm May be lost with the water flow. If it is too low, the clay coating layer cannot be completely removed. Due to the forced stirring effect of the spiral blades, the water consumption per unit processing volume of the spiral sand washing machine needs to be controlled at 2-3m³/t. Meanwhile, by adjusting the branch valves of the flushing water pipes, the “coarse flushing – fine flushing” segmented water supply is achieved. In the coarse flushing stage, 60% of the total water is used to remove large particle impurities, and in the fine flushing stage, 40% of the water is used to precisely purify the surface.

The mud content of raw materials is the core basis for water volume regulation: when the mud content is ≤5%, 80% of the benchmark water volume can be maintained for operation. When the mud content rises to 10%-15%, the flow rate should be increased to 1.2 times and the flushing time extended to 4-5 minutes. If the mud content exceeds 20%, a pre-screening device should be used for pretreatment to avoid the problem of low pulp concentration caused by excessive water use.

(2) Key Points for the Construction of Dynamic Control Systems

Precise regulation and control rely on a closed-loop system of “monitoring – feedback – execution” : An electromagnetic flowmeter is installed at the water inlet of the sand washing machine to monitor the flow fluctuation in real time (with an accuracy of ±0.5%), and the moisture content of the finished sand is tracked by an online moisture content detector. When the moisture content deviates from the standard range of 4%-6%, the system automatically adjusts the speed of the variable frequency water pump to achieve millisecond-level response adjustment of water volume.

For intermittent production scenarios, a water level buffer device should be set up: the effective volume of the circulating water tank should not be less than the processing capacity of the equipment for 15 minutes. Through the linkage of the liquid level sensor and the make-up water valve, the water level in the tank should be kept stable within ±5cm to avoid the imbalance of water supply and demand caused by fluctuations in the feed volume.

Second, the design and optimization of water resource recycling systems

An efficient circulation system can reduce the amount of fresh water replenishment to less than 5% of the total water consumption. The core lies in building a process system of “hierarchical treatment – precise reuse – zero discharge closed-loop”.

(1) Core configuration of the three-stage water treatment process

Pretreatment stage: The sand washing wastewater first enters the cyclone group, where fine sand with a particle size of ≥0.075mm is separated under the action of centrifugal force, with a recovery rate of over 85%, and at the same time, the solid content of the wastewater is reduced by 40% to 60%. The feed pressure of the cyclone should be stabilized at 0.2-0.3MPa, and the flow rate at the overflow outlet should be controlled at 1.5-2.0m/s to prevent excessive classification of fine particles.

Concentration stage The pre-treated wastewater enters the high-efficiency thickening tank. By adding 50-80 PPM of PAC (polyaluminium chloride) and 1-3 PPM of PAM (polyacrylamide), flocs form and settle within 3-5 minutes. The turbidity of the supernatant can be reduced to below 25NTU, and the underflow concentration is controlled at 25%-30%, laying the foundation for subsequent dewatering treatment. The surface loading of the thickening tank should be designed at 1.5-2.0m³/(m² · h) to ensure that the sedimentation efficiency matches the processing capacity.

In the advanced treatment stage, the concentrated underflow is sent into the high-pressure filter press by a screw pump and continuously subjected to a pressing pressure of 6-8 mpa for 20-30 minutes, forming a mud cake with a moisture content of ≤15% and a filtrate turbidity of ≤20NTU, which can be directly reused in the sand washing stage. For high-demand scenarios, a membrane treatment system can be added to ensure that the effluent quality meets drinking water standards and expand the reuse scenarios.

(2) Energy-saving and Adaptive Design of the circulation system

Separating clear and turbid water is a key strategy to reduce processing energy consumption: connect the spray clear water of the sand washing machine and the equipment cooling water to the clear water network for direct reuse. The wastewater containing sludge enters the treatment system separately to avoid the increase in treatment costs caused by the mixture of clear water and sewage. The pipeline design should adopt the principle of “large pipe diameter and low flow rate”. The flow rate of the main pipeline should be controlled at 1.2-1.5m/s to reduce the head loss along the way and lower the energy consumption of the circulating water pump by 15%-20%.

The system adaptation solutions for different production capacity scenarios vary: For small production lines (≤100t/h), a combination of “cyclone + sedimentation tank + filter press” can be adopted, with an equipment investment payback period of approximately 12 months. For large-scale production lines (≥500t/h), a deep cone thickener + ceramic filter + centrifuge system should be configured to handle over 300m³ of wastewater per hour. At the same time, an evaporation pool system should be provided to balance water loss, truly achieving zero discharge.

Third, maintenance management and efficiency improvement of system operation

A well-developed operation and maintenance system can extend the lifespan of the circulation system to over 8 years while maintaining a reuse efficiency of over 95%.

(1) Maintenance specifications for key equipment

The high-frequency dewatering screen needs to clean the screen mesh every 200 to 300 hours of operation and check the flatness of the screen surface (error ≤2mm/m) to avoid the decrease in processing efficiency caused by clogged holes. The filter cloth of the filter press should be replaced regularly according to the nature of the feed. When the filtration cycle is extended by 30% or the turbidity of the filtrate exceeds the standard, the damage to the filter cloth should be checked in time.

The calibration of the chemical dosing system is of vital importance: the optimal ratio of PAC to PAM should be verified through beaker tests every week. When the SS (suspended solids) concentration of the raw water fluctuates beyond 5000mg/L, the dosage should be readjusts to avoid increased viscosity of the filter cake and rising costs caused by excessive medication.

(2) Implementation Paths of Digital Management

Introduce a PLC control system to achieve full-process automation: Through real-time data feedback from the turbidity online meter and the electromagnetic flowmeter, automatically adjust the dosage of chemicals and the speed of the water pump. Set up the “one-click plate pulling” function in the filter press system, and in combination with the belt weighing device, upload the real-time output data of the mud cake to the cloud management platform.

Establish standardized operation ledgers: Record 12 key data items such as processing volume, influent and effluent turbidity, and chemical consumption for each shift. Identify system bottlenecks through trend analysis. For instance, when the reuse rate of circulating water drops by more than 5%, prioritize checking the operation status of the cyclone overflow outlet and the sludge discharge valve of the thickening tank.

Fourth, the environmental and economic benefits of technological upgrading

The investment in a water resource recycling system can bring about significant dual benefits: At the environmental level, a system with a reuse rate of ≥95% can reduce sewage discharge by more than 100,000 cubic meters annually. When the moisture content of the mud cake is ≤30%, solid waste can be recycled and utilized for brick-making or roadbed backfilling. At the economic level, calculated at 3 yuan per cubic meter for industrial water use, a medium-sized production line can save over 450,000 yuan in water fees annually. Meanwhile, the additional income brought by fine sand recovery can shorten the payback period of investment to 3 to 6 months.

With increasingly strict environmental protection regulations, standards such as “Sand for Construction” (GB/T14684-2022) have put forward clear requirements for the discharge and reuse of production water. Scientific water volume control and recycling plans are no longer optional configurations but the core support for enterprises to achieve compliant production and enhance their competitiveness. Through precise parameter regulation, system optimization design and digital operation and maintenance, a virtuous cycle of “efficient production – resource conservation – environmental friendliness” can be constructed, providing key technical support for the sustainable development of the sand and gravel processing industry.

Post time: Oct-27-2025