Sand washing machine equipment is a kind of sand and gravel cleaning device widely used in construction, water conservancy, highway and other industries. It cleans the sand through steps such as cleaning and dewatering. However, the correct use and maintenance of sand washing machine equipment are of vital importance for extending the equipment’s lifespan, enhancing work efficiency and ensuring production safety. This article will provide a detailed introduction on how to correctly operate the sand washing machine equipment.

First, understand the working principle and structure of the sand washing machine equipment

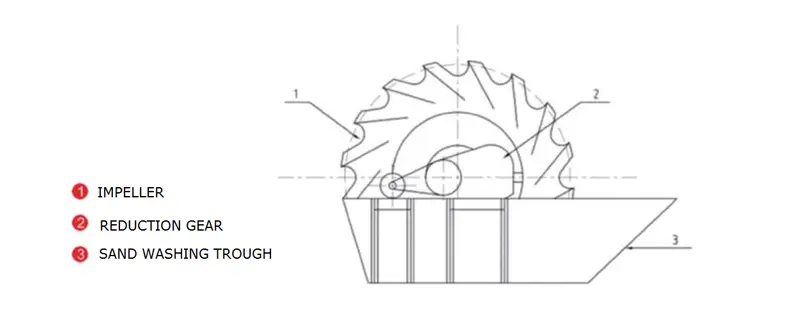

The sand washing machine equipment mainly consists of the feeding device, cleaning device, dewatering device, transmission device and control system, etc. The working principle is as follows: Sand and gravel enter the cleaning device through the feeding device. In the cleaning device, the sand and gravel come into full contact with water. Through the scouring effect of the water flow, impurities such as soil and stone powder on the surface of the sand and gravel are removed. The washed sand and gravel enter the dewatering device, where the moisture on the surface of the sand and gravel is removed to achieve a certain degree of dryness. Finally, the sand and gravel that have undergone dehydration treatment are discharged through the discharge device.

Second, arrange the positions of the equipment reasonably

The layout of the sand washing machine equipment should be reasonable, and it should be ensured that there is sufficient space around the equipment for operation and maintenance. In addition, the installation location of the equipment should be as close as possible to water sources, power sources and raw material production areas to facilitate water intake, power supply and material feeding during the production process. Meanwhile, the drainage pipes of the equipment should be connected smoothly to prevent water accumulation from causing damage to the equipment.

Third, maintain and service the sand washing machine equipment

After choosing the appropriate sand washing machine equipment, correct maintenance and care are also an important part of extending the equipment’s lifespan and improving its efficiency. Proper maintenance and care can help reduce machine malfunctions and maintenance costs, thereby enhancing the performance of the sand washing machine equipment. First of all, regularly maintain and inspect the machine to ensure the normal operation of all components of the equipment. Secondly, when cleaning equipment, appropriate cleaning agents and tools should be used. Hard objects or cleaning products containing acidic or alkaline components should be avoided to prevent corrosion or wear to the equipment. In addition, users need to accurately grasp the frequency and intensity of equipment usage to avoid exceeding its designed load and causing damage to the equipment.

Post time: Aug-07-2025