In modern construction and road construction, the demand for sand and gravel as basic building materials is increasing day by day. High-quality sand and gravel are one of the keys to ensuring the quality of the project. The traditional sand washing methods are inefficient and cannot meet the demands of large-scale production. Therefore, the emergence of Gaoke Machinery’s wheeled sand washing machine has become a revolution in the industry. This article will delve into how this innovative equipment enhances the efficiency of sand and gravel washing and selection, and analyze its positive impact on the development of the industry.

First, the working principle of Gaoke Machinery’s wheeled sand washing machine

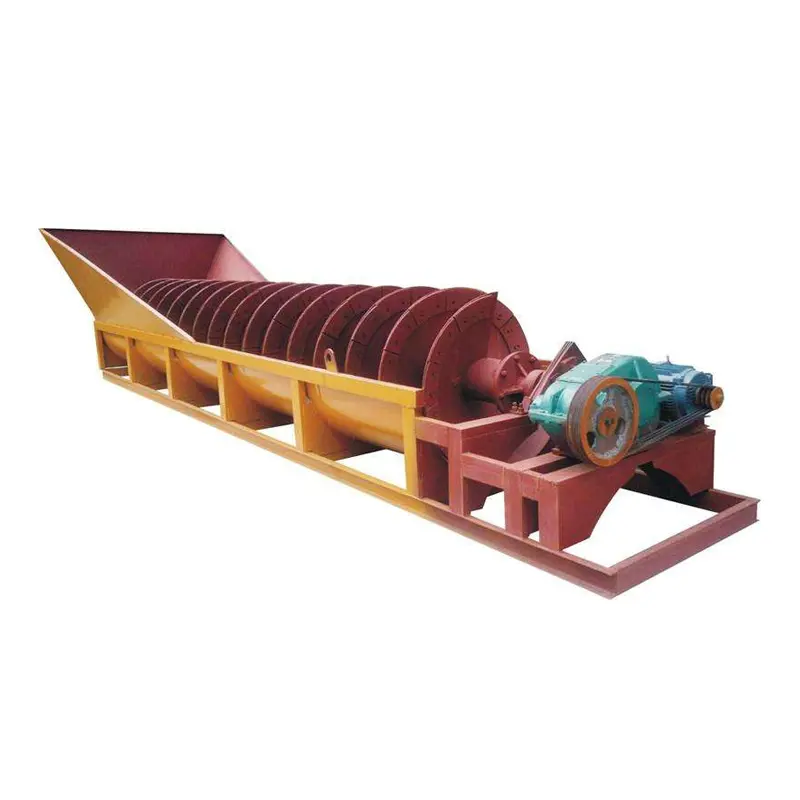

The Gaoke Machinery wheel-type sand washing machine adopts a wheel-type structure. Its main components include the feeding system, washing and selection system, slag discharge system and control system. Its working principle is simple and clear: Firstly, the raw materials are sent into the machine through the feeding system. Then, under the action of the washing and selection system, the raw materials are mixed with water by the high-speed rotating wheel disk, and the impurities and soil in the sand and gravel are effectively separated. Finally, after being processed by the slag discharge system, the clean sand and gravel are conveyed to the destination, completing the entire washing and selection process. Throughout the entire process, the control system can intelligently monitor and adjust the washing machine, ensuring the stability and controllability of the washing effect.

Second, the application advantages of Gaoke Machinery’s wheeled sand washing machine

1. Enhance the utilization rate of mineral resources: The Gaoke Machinery wheel-type sand washing machine can ensure that the machine sand reaches the construction volume while increasing the sand washing volume and reducing the sand making cost. This is conducive to making full use of resources such as river pebbles and limestone, and fully protecting natural sand and gravel resources.

2. Improve the quality of sand and gravel: The sand and gravel washed by the wheeled sand washing machine of Gaoke Machinery have more uniform cleanliness and particle size distribution, meeting the standards for construction sand. This is conducive to improving the quality of construction and reducing the engineering risks caused by the quality problems of sand and gravel.

3. Reduce maintenance costs: The Gaoke Machinery wheel-type sand washing machine has a simple structure, few vulnerable parts, and requires less maintenance work. In addition, as the impeller drive bearing device is isolated from water and water-receiving materials, the probability of bearing damage is reduced, further lowering maintenance costs.

Third, methods to enhance the working efficiency of Gaoke Machinery’s wheeled sand washing machine

1. Prevent debris from entering: During the sand washing process, it is necessary to prevent high-hardness materials and other impurities from entering the sand washing equipment to avoid affecting the cleaning effect of the finished product and the service life of the sand washing machine.

2. Reasonable control of liquid level: The liquid level of the sand washing machine has a significant impact on the cleaning effect. A liquid level that is too low will affect the sand washing effect, while a liquid level that is too high will waste water resources and easily cause sand and gravel to overflow. Therefore, the liquid level of the sand washing machine should be reasonably controlled to ensure a balance between the cleaning effect and the utilization rate of water resources.

3. Adjust the ore concentration: The ore concentration is a key factor that needs to be adjusted during the operation of the sand washing machine. By adjusting the ore concentration to the critical value, the processing capacity and classification accuracy of the sand washing machine can be optimized.

Post time: May-13-2025