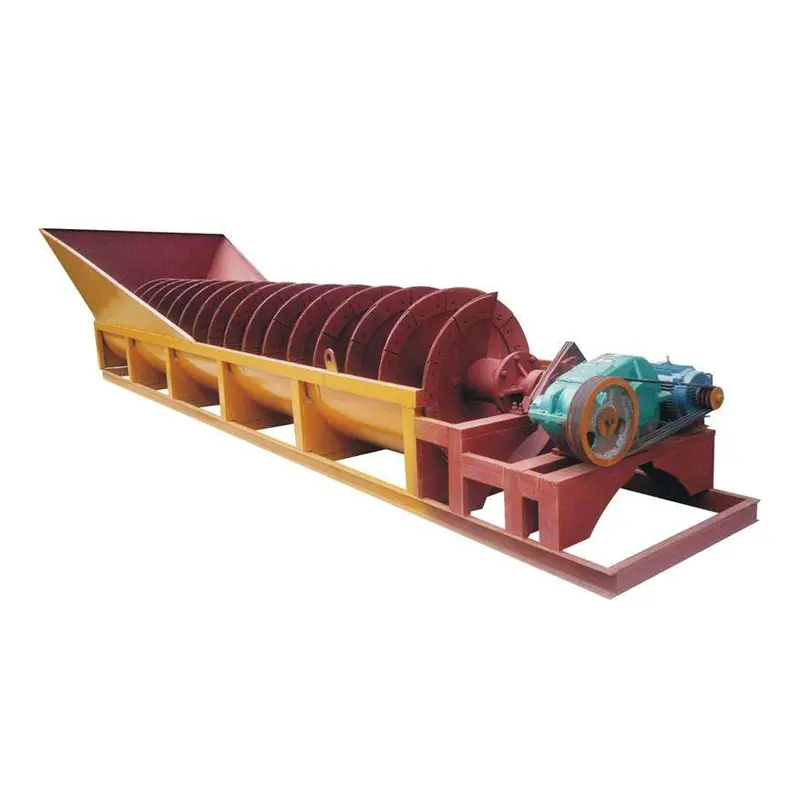

In the production process of construction sand, sand washing machines are indispensable equipment, used to remove soil, impurities and fine particles from sand and gravel, ensuring the quality of construction sand. With the advancement of technology, spiral sand washing machines have gradually become the mainstream choice in the market. Compared with traditional sand washing machines, they have significant advantages in many aspects. This article will make a detailed comparison of the specific advantages of spiral sand washing machines and traditional sand washing machines.

First, the cleaning effect

1.Spiral sand washing machine

The spiral sand washing machine can efficiently remove soil, impurities and fine particles from sand and gravel through the dual action of water flow and spiral blades. Its cleaning effect is significantly better than that of traditional sand washing machines, and it can ensure that the purity and particle size distribution of construction sand meet the standard requirements. The rotation of the spiral blades not only increases the impact force of the water flow but also further separates impurities through mechanical stirring, ensuring the cleaning effect.

2. Traditional sand washing machine

Traditional sand washing machines usually adopt simple water washing or drum cleaning methods, and the cleaning effect is relatively poor. These devices mainly rely on the impact force of water flow for cleaning, lacking mechanical stirring effect, making it difficult to thoroughly remove soil and fine particles from the sand and stones, resulting in a relatively low purity of the cleaned sand and stones.

Second, energy conservation and environmental protection

1.Spiral sand washing machine

The spiral sand washing machine is designed with emphasis on energy conservation and environmental protection. It consumes less energy during operation and treats wastewater through a recovery system, reducing the waste of water resources and environmental pollution. This environmentally friendly sand washing method meets the requirements of modern society for sustainable development.

2. Traditional sand washing machine

Traditional sand washing machines usually do not come with a wastewater recovery system. The wastewater generated during the cleaning process is directly discharged, which not only wastes water resources but may also cause environmental pollution. In addition, the energy consumption of traditional sand washing machines is relatively high, and their operating costs are also higher.

Third, the degree of automation

1.Spiral sand washing machine

Modern spiral sand washing machines are usually equipped with advanced control systems and can achieve automated operation. Operators can easily adjust the operating parameters of the equipment, such as the screw speed and water flow rate, through the control panel to adapt to different sand and stone characteristics and cleaning requirements. This kind of automated operation not only enhances production efficiency, but also reduces manual intervention and lowers labor intensity.

2. Traditional sand washing machine

The operation of traditional sand washing machines is usually rather complicated and requires frequent manual adjustment of the equipment’s operating status. These devices lack an automatic control system. Operators need to manually adjust parameters such as water flow and drum speed, which increases the labor intensity and operational difficulty.

Fourth, it has a compact structure and occupies a small area

1.Spiral sand washing machine

The structure design of the spiral sand washing machine is compact and it occupies a relatively small area. This is an important advantage for sand and gravel yards with limited space, enabling efficient sand washing operations within a limited space. Its compact design not only saves site space but also facilitates the installation and maintenance of equipment.

2. Traditional sand washing machine

The structure of traditional sand washing machines is relatively large and they occupy a considerable area. Especially for the drum-type sand washing machine, a relatively large space is required to accommodate the drum and the supporting equipment. This not only limits the installation location of the equipment, but also increases the site cost.

Fifth, maintenance costs

1.Spiral sand washing machine

The maintenance of the spiral sand washing machine is relatively simple. The wear of the main components such as the spiral blades and the water tank is small, and the service life is long. Its automated control system reduces manual operation and lowers the risk of equipment damage caused by improper operation. In addition, the spiral sand washing machine has a compact structure, which is convenient for maintenance and repair, reducing maintenance time and costs.

2. Traditional sand washing machine

The maintenance of traditional sand washing machines is rather complicated, especially for drum-type sand washing machines. The rollers wear out quickly and need to be replaced regularly. In addition, the operation of traditional sand washing machines is complex, and they are prone to damage due to improper operation, which increases maintenance costs.

Sixth, production efficiency

1.Spiral sand washing machine

The high-efficiency cleaning capacity and automated operation of the spiral sand washing machine can significantly enhance production efficiency. The rotation of its spiral blades not only increases the impact force of the water flow but also further separates impurities through mechanical stirring, ensuring the cleaning effect. The automatic control system can automatically adjust the operating parameters according to the characteristics of different sand and gravel, further improving the production efficiency.

2. Traditional sand washing machine

The cleaning efficiency of traditional sand washing machines is relatively low. They mainly rely on the impact force of water flow for cleaning and lack mechanical stirring effect, making it difficult to thoroughly remove impurities from sand and gravel. In addition, the operation of traditional sand washing machines is complex, requiring frequent manual adjustments to the equipment’s operating status, which increases operation time and labor intensity, and reduces production efficiency.

The spiral sand washing machine has significant advantages over traditional sand washing machines in many aspects, including more efficient cleaning effect, energy-saving and environmentally friendly design, high degree of automation, compact structure, low maintenance cost and high production efficiency. These advantages have made the spiral sand washing machine gradually become the mainstream choice in the field of construction sand, capable of providing high-quality construction sand for sand and gravel yards while reducing production costs, which meets the requirements of modern society for sustainable development. It is hoped that the introduction in this article can help you better understand the advantages of the spiral sand washing machine and provide a reference for your sand and gravel yard to choose the appropriate sand washing equipment.

Post time: May-21-2025