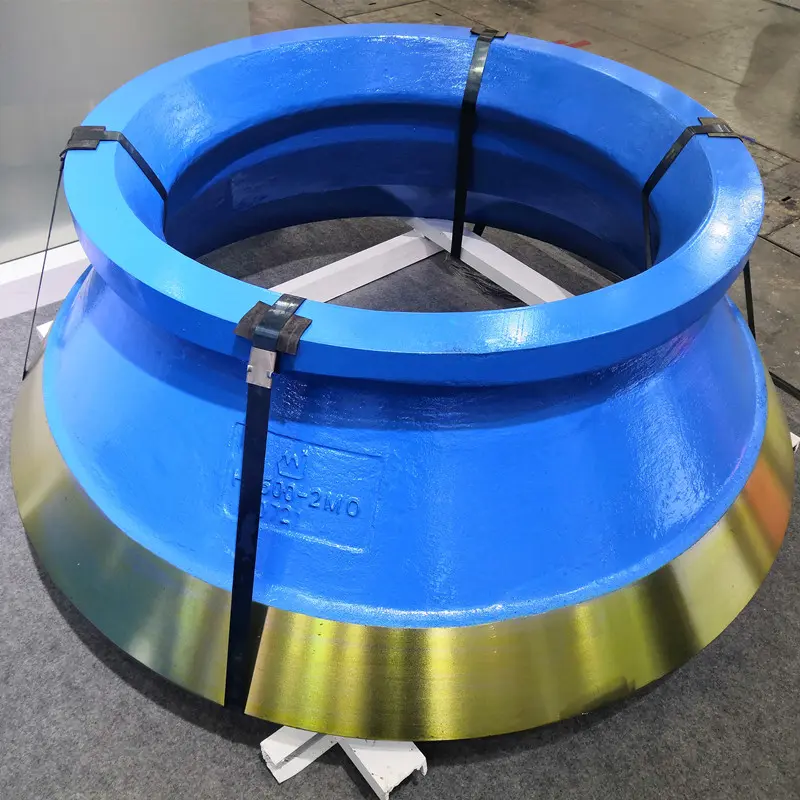

In the daily maintenance of the mill, regularly inspecting the wear of the concave gasket is a key link to ensure the stable operation of the equipment and extend its service life. Wear detection can be carried out in various ways, including visual inspection, thickness measurement and ultrasonic testing, etc. This article will provide a detailed introduction to these detection methods and explain how to promptly identify and replace severely worn gaskets through these methods, thereby effectively extending the service life of the mill.

First, visual inspection: An intuitive preliminary judgment

1.1 Check for wear marks

Visual inspection is the most intuitive detection method. By observing the wear marks, cracks and deformation on the surface of the gasket, the degree of wear of the gasket can be preliminarily judged. Wear marks are usually manifested as unevenness, grooves or depressions on the surface, which indicate that the liner has undergone a certain degree of wear.

1.2 Check for cracks and deformations

In addition to wear marks, it is also necessary to check whether there are cracks or deformations on the surface of the gasket. Cracks may be caused by long-term mechanical stress or thermal stress, while deformation may result from the aging or uneven wear of the gasket material. All these situations may affect the performance of the gasket and even lead to its early failure.

Second, measure thickness: Accurately assess the degree of wear

2.1 Use a thickness gauge

To gain a more accurate understanding of the actual wear of the gasket, it is recommended to use a dedicated thickness gauge to measure multiple parts of the gasket. The thickness gauge can provide precise thickness data, helping you accurately assess the wear of the gasket.

2.2 Record the data and make comparisons

When measuring thickness, it is recommended to conduct multiple measurements at different parts of the gasket to obtain comprehensive wear data. Record the measurement results and compare them with the original thickness of the gasket to determine the degree of wear. If the thickness of a certain part decreases by more than 30% of the original thickness, it indicates that the gasket of that part has been severely worn and needs to be considered for replacement.

Third, ultrasonic testing: Non-destructive testing technology

3.1 Detect internal cracks and defects

Ultrasonic testing is a non-destructive testing technology that can detect cracks and defects inside gaskets. This technology assesses the internal structure of materials by emitting ultrasonic waves and receiving reflected waves. Ultrasonic testing can detect potential damage risks in advance, helping you take measures before problems worsen.

3.2 The Importance of Regular Testing

Regular ultrasonic testing can ensure that the internal structure of the gasket remains in good condition. It is recommended to conduct ultrasonic testing every six months, especially when the operating environment of the mill is harsh or the gasket has been in use for a long time. Through regular inspection, potential problems can be detected and dealt with in a timely manner, avoiding damage to the mill cylinder caused by damaged gaskets.

Fourth, maintenance suggestions

4.1 Replace severely worn gaskets in a timely manner

Regular wear detection is the key to promptly identifying and replacing severely worn gaskets, which is crucial for extending the service life of the mill. Severely worn gaskets not only affect the efficiency of the mill but may also cause damage to the mill cylinder. Therefore, once the wear of the gasket exceeds the safety range, it should be replaced immediately.

4.2 Record and maintain data

It is recommended to establish detailed maintenance records, including the time of each inspection, wear data and replacement status. These records can help you better understand the wear pattern of the gasket, optimize the maintenance plan, and reduce unnecessary maintenance costs.

4.3 Train operators

Ensure that the operators are familiar with the methods and significance of wear detection and can correctly carry out the detection work. Regular training for operators to enhance their maintenance skills and safety awareness helps ensure the stable operation of the mill.

Regular inspection of the wear condition of the concave gasket is a key link to extend the service life of the mill. The degree of wear of the gasket can be comprehensively evaluated through various methods such as visual inspection, thickness measurement and ultrasonic testing. Timely detection and replacement of severely worn gaskets can not only enhance the operational efficiency of the mill but also effectively extend the service life of the equipment and reduce maintenance costs. It is hoped that the detection methods and maintenance suggestions provided in this article can help you better manage the maintenance work of the mill and ensure the long-term stable operation of the equipment.

Post time: Jul-24-2025