Mining Machine–Ball Mill Parts-Mill Liners

Product Description

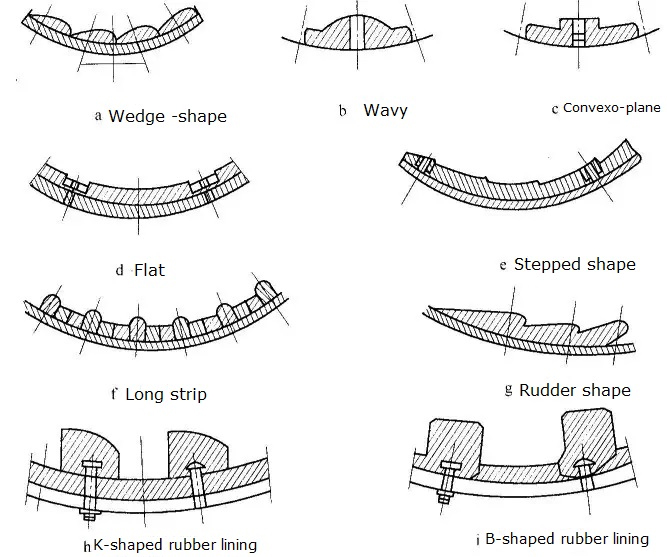

In order to adapt to the requirements of different working states (crushing or fine grinding), the shape of the liner is different. When crushing is the main task, it is required that the liner has strong pushing ability to the grinding body, and the liner should have good impact resistance. When the main grinding is fine, the highlight of the liner is relatively small, the pushing effect of the grinding body is weak, the impact is small, the grinding effect is strong, and the liner is required to have good wear resistance. The advanced designed production process, including intelligent weighting system of furnace, fully computerized control system of heat treatment, fast-quenching cooling system, etc, which are the fundamental for the quality guarantee of our products.

Our company is one of the largest production bases of wear-resistant steel castings in China, with the annual production of about 40,000 tons of various wear-resistant steel castings, including high manganese steel, alloy steel, cast iron, high chromium cast iron, medium chromium cast iron, etc., WUJ accepts customized drawings and can also arrange technicians to conduct physical measurement and mapping on site.

Main materials (can be produced according to customer requirements)

|

Element |

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Mo |

Al |

Cu |

Ti |

|

Mn13 |

1.10-1.15 |

0.30-0.60 |

12.00-14.00 |

<0.05 |

<0.045 |

/ |

/ |

/ |

/ |

/ |

/ |

|

Mn13Mo0.5 |

1.10-1.17 |

0.30-0.60 |

12.00-14.00 |

≤0.050 |

≤0.045 |

/ |

/ |

0.40-0.60 |

/ |

/ |

/ |

|

Mn13Mo1.0 |

1.10-1.17 |

0.30-0.60 |

12.00-14.00 |

≤0.050 |

≤0.045 |

/ |

/ |

0.90-1.10 |

/ |

/ |

/ |

|

Mn13Cr2 |

1.25-1.30 |

0.30-0.60 |

13.0-14.0 |

≤0.045 |

≤0.02 |

1.9-2.3 |

/ |

/ |

/ |

/ |

/ |

|

Mn18Cr2 |

1.25-1.30 |

0.30-0.60 |

18.0-19.0 |

≤0.05 |

≤0.02 |

1.9-2.3 |

/ |

/ |

/ |

/ |

/ |

| And other high chromium materials and alloy steel materials you need | |||||||||||